the world’s best tech for the world’s best farmers

driving efficiency

Setting the standard for reliability.

Efficient, reliable and hard-wearing, our range of Compact sprayers is designed to provide you with the confidence to take on weed after weed. Knapsacks, Utility Sprayers, Three-Point Linkage and more.

Spraying solutions to drive efficiency.

We’ve been building sprayers for half a century. In that time, our range has continually evolved to meet the changing needs of Australian growers. Discover our solutions today.

Browse our range

WEED-IT Optical Spot Spraying

discover more

Self Propelled Sprayers

discover more

Broadacre Trailed Sprayers

discover more

Viticulture and Horticulture Sprayers

discover more

Three-Point Linkage Sprayers

discover more

Utility Sprayers

discover more

Accessories, Components and Tools

discover more

Used Equipment

discover moreFIND A CROPLANDS DEALER

You can expect the very best local support from the Croplands dealer network. With dealers located all around the country, high-quality technical support, parts and accessories are always close to hand.

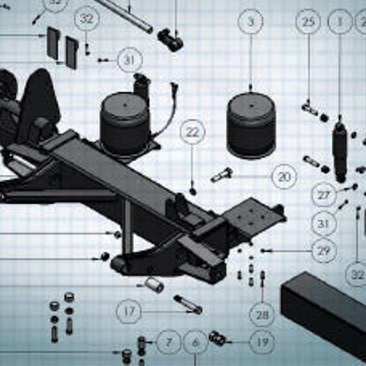

search parts information

Find the information you need to identify, service or order replacement parts for your sprayer.

News and Events

Croplands Autonomous Spray Solution – Prospr

Croplands and Robotics Plus partner to introduce Prospr to the Australian horticulture market.

Croplands joins forces with MagrowTec

Croplands, leading spray equipment manufacturer, and MagrowTec, leaders in magnetically assisted spray technology, are pleased to announce their new partnership, joining forces to bring MagrowTec to Australian and New Zealand growers.

Avocados in great shape with Croplands Cropliner

Loffler Fresh sell 50,000 trays of avocados a year. A feat that is made possible with their Cropliner XL tree crop sprayer.